Application

The model 8405 is designed to mix two non-flammable, non-corrosive gases. Common applications are welding shield gas, food packaging, leak detection and blanketing atmospheres.

Because the gas mixer uses a surge tank design, this type of system is ideal for applications that require maintaining a precise proportion from zero flow to full flow with high reliability. The 8405 is suitable for continuous flow or intermittent flow demand.

The model 8405 is designed for

both indoor and outdoor

installation.

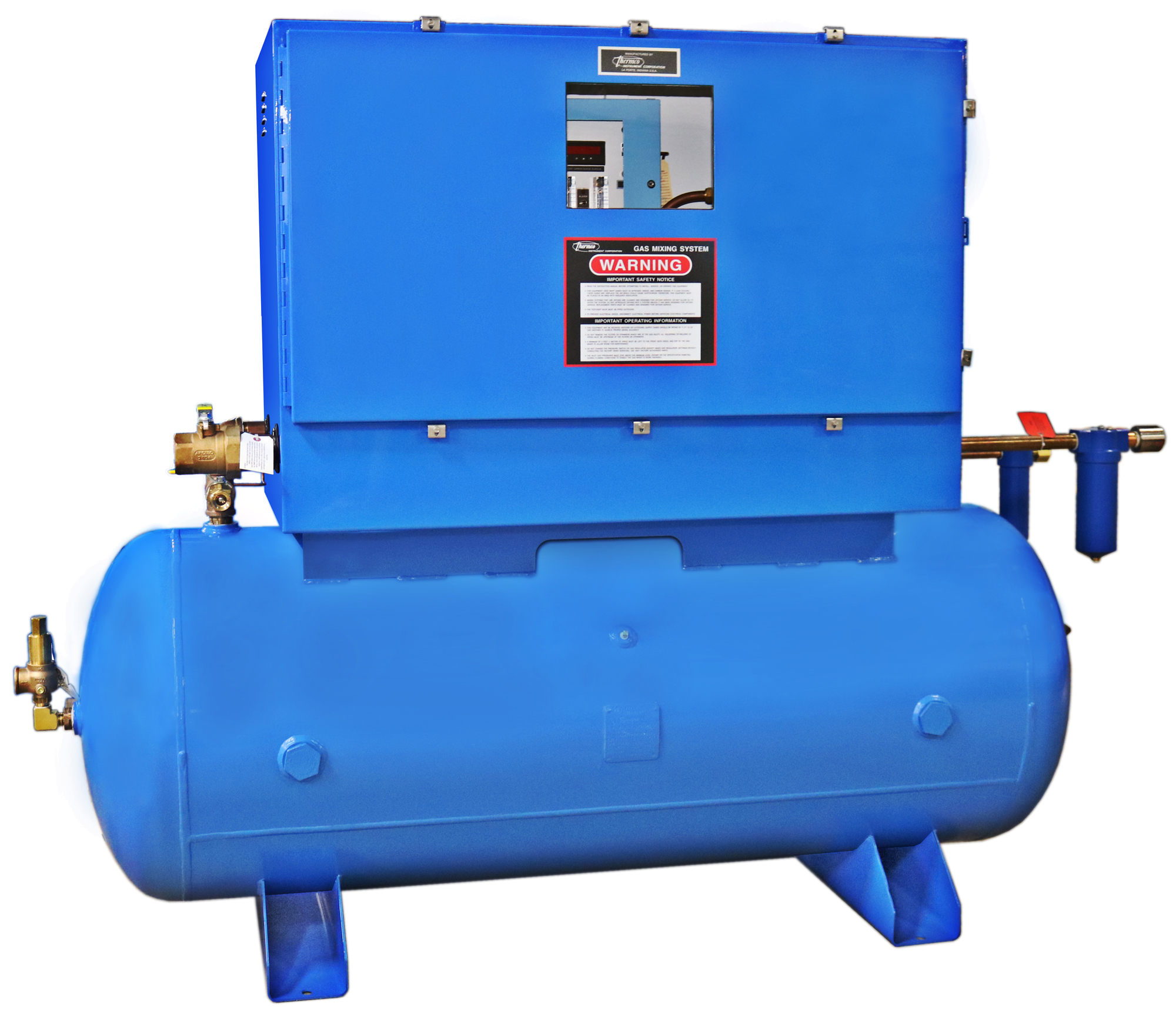

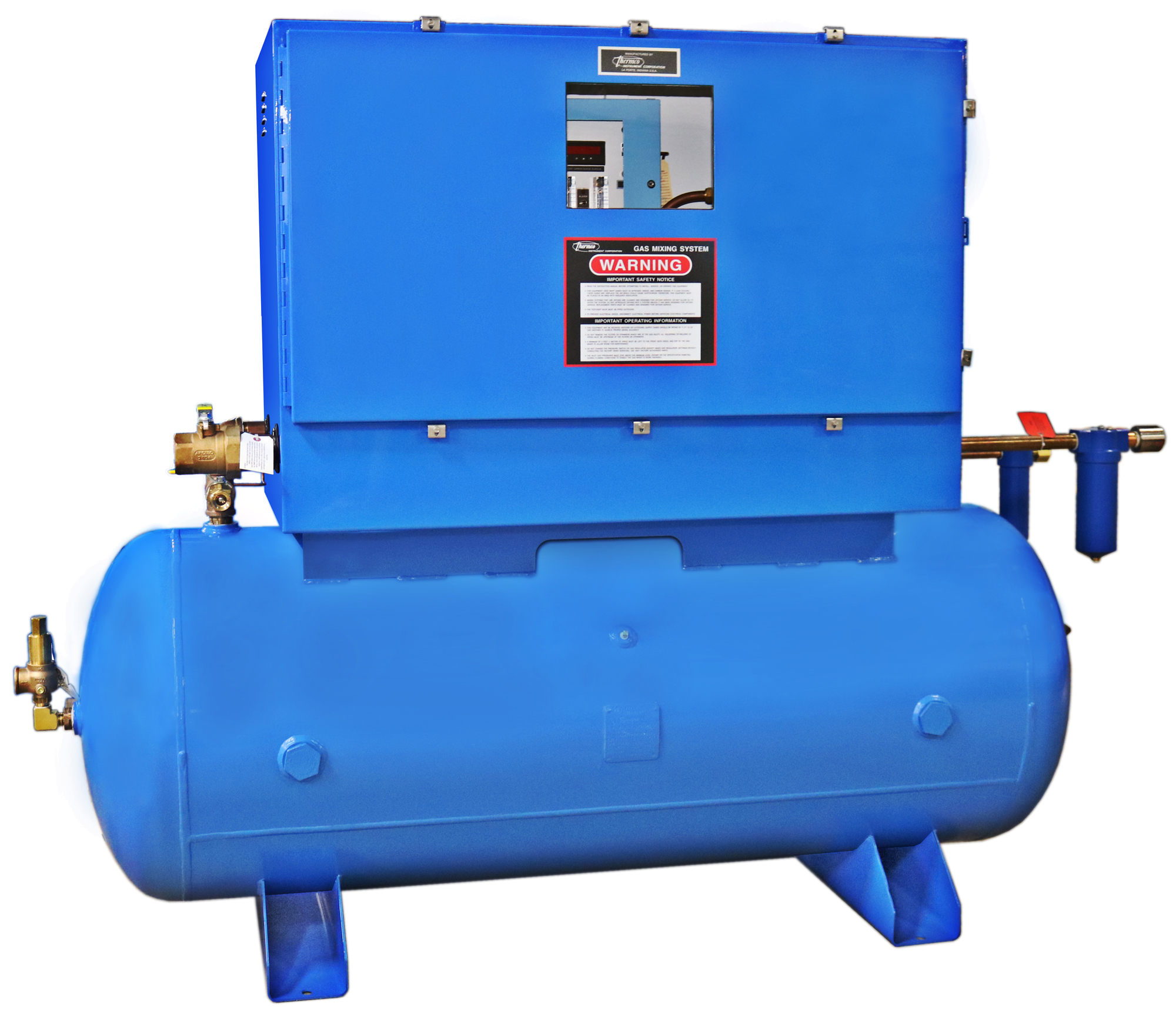

Thermco Surge Tank System

All Thermco gas mixers use a surge tank. The Thermco surge tank system has the significant advantage of maintaining the accuracy of the gas mixture from zero to full rated flow rate. There is no “minimum” flow rate. Gas mixing systems without a surge tank will have a minimum flow rate below which the gas mixture becomes inaccurate. The Thermco surge tank system is able to accomplish this accuracy without complex control valves or flowmeters.

Standard Supply Gas Pressure

Gas mixers will be made for supply pressures of 120-145 psig (8.3-10.0 barg) and mixed gas output pressures of 30-50 psig (2.1-3.4 barg) unless ordered otherwise. Gas mixers are often made to special pressure conditions; consult Thermco for details.

Documentation

Each gas mixer is supplied with one instruction manual which includes wiring and flow diagrams. A data sheet is prepared for each gas mixer specifying major parts of the gas mixer, operating pressure settings and recommended spare parts. Thermco has been providing service on gas mixers since 1964.

Warning

Improper use of this product can cause death, serious injury, or property damage. Personnel dealing with this equipment should read and understand warning labels and instruction manuals provided by Thermco. Only personnel familiar with industrial gases should attempt to install or service this equipment. Gases are under pressure and therefore the hazards associated with pressurized systems exist. Gases from high pressure cylinders must be reduced to the specified pressure before entering the gas mixing system to prevent the possibility of equipment damage and personal injury.

Only use oxygen in gas mixers specifically designed for oxygen service. Gas mixers not designed for oxygen service cannot be converted to oxygen service.

Flammable, toxic, liquid or corrosive gases should not enter these gas mixing systems.

Ordering Information

Thermco gas mixers are available through many local industrial gas suppliers. Thermco gas mixers may also be ordered directly from the factory. It is especially important to order the correct pressure conditions for the application. If there are questions, please contact the Thermco Sales Engineer.